“It works on my desk.”

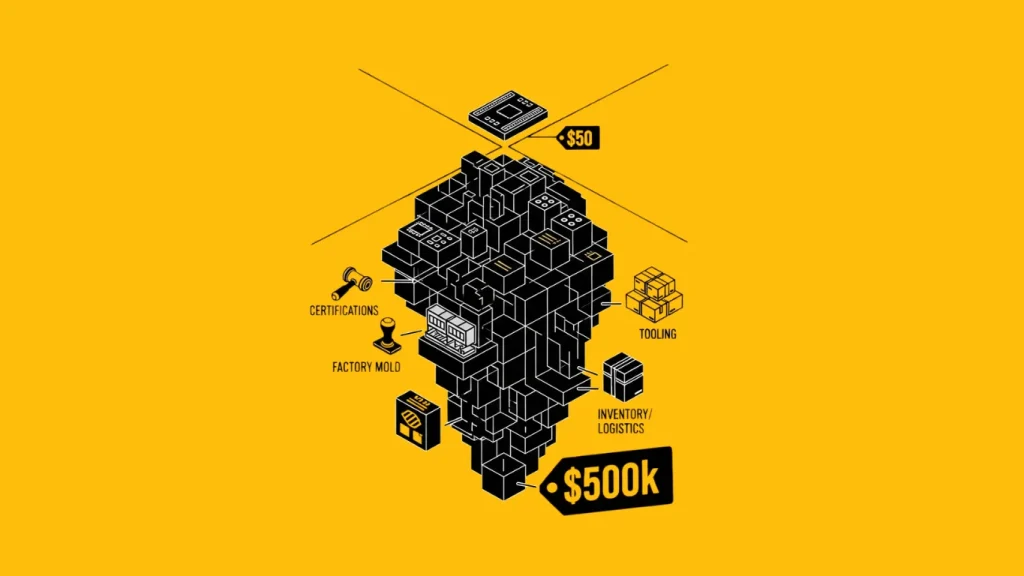

While working on embedded device, this is simultaneously the most exciting and the most dangerous sentence. You’ve built a proof-of-concept (PoC). It connects to the cloud, sends sensor data, and the Bill of Materials (BOM) for the components on your breadboard is only $50.

The math seems simple: If we want to build 10,000 units, we just need $500,000, right?

Wrong. This “Prototype Fallacy” is the primary reason why promising IoT startups fail and why enterprise hardware initiatives run over budget. Most advice out there is vague, glossing over the messy reality of certifications, data plans, and reverse logistics.

The journey from a functional prototype to a mass-manufactured product is not a linear scaling of unit costs; it is a chasm filled with Non-Recurring Engineering (NRE), compliance hurdles, and supply chain complexities.

At Better Devices, we believe in radical transparency. Here is the realistic breakdown—including the hidden costs no one talks about—of why that $50 prototype might actually require a $500k investment before the first unit rolls off the assembly line.

1. The NRE Iceberg: Design for Manufacturing (DFM)

Your prototype was likely built with development boards (like an ESP32 dev kit or Raspberry Pi) and 3D-printed enclosures. These are great for validation, but impossible to manufacture at scale.

To go to production, you must redesign everything:

- Custom PCB Design: You need a custom Printed Circuit Board (PCB) to reduce size and cost. This involves schematic capture, layout, and signal integrity analysis.

- Mechanical Tooling: 3D printing is slow and expensive per unit. Injection molding is cheap per unit but requires massive upfront investment. A single steel mold for a plastic enclosure can cost between €10,000 and €50,000 depending on complexity and surface finish.

- DFM Reviews: Optimizing the design so robots (and humans) can assemble it quickly without errors.

Estimated Cost: €50k – €150k

2. The “Alphabet Soup” of Certification (CE, FCC, RED)

In the EU and Germany, you cannot legally sell an electronic device without the CE mark. This isn’t just a sticker; it’s a declaration of conformity backed by rigorous lab testing.

- EMC/EMI Testing: Proving your device doesn’t emit harmful radio interference and isn’t susceptible to it.

- Radio (RED) & Safety: Ensuring your Wi-Fi, Bluetooth, or Cellular radios meet spectrum regulations and that the battery won’t catch fire.

- Bluetooth SIG: If you use the Bluetooth logo, you must pay qualification fees ($8k-$10k).

- Cellular (PTCRB/GCF): If your device uses LTE-M or NB-IoT, carrier certifications are mandatory and expensive.

Failing a test means redesigning the board and paying the lab fees again.

Estimated Cost: €20k – €100k (depending on radio complexity)

3. The Scale Multiplier: A Hypothetical Case Study (1k vs 100k Units)

To illustrate the hidden impact of scale, let’s look at a hypothetical “Smart Industrial Tracker.” While mass production lowers component costs, it explodes your operational risks and recurring liabilities.

| Cost Category | 1,000 Units (Pilot Run) | 100,000 Units (Mass Scale) | The Hidden Reality |

| BOM per Unit | $60 (Distributor pricing) | $45 (Direct manufacturer pricing) | Margins improve, but capital risk skyrockets. You now have $4.5M tied up in inventory. |

| NRE Impact | $100/unit ($100k amortized) | $1/unit ($100k amortized) | NRE kills low-volume economics. You essentially pay double per unit in the pilot phase. |

| Connectivity (Data) | $2/mo per device | $1/mo per device | $2k/month vs. $100k/month. At scale, a “cheap” data plan becomes a massive monthly liability ($1.2M/year). |

| Returns (1% Failure) | 10 Units | 1,000 Units | 10 broken units is a box on your desk. 1,000 broken units is a warehouse logistics nightmare requiring a dedicated team. |

| Certifications | $50k Fixed Cost | $50k Fixed Cost | A huge burden for the pilot, negligible for mass scale. |

Scale solves margin problems but creates cash flow and logistics problems. A 1% failure rate is negligible at 1,000 units but can bankrupt a support department at 100,000.

Try the Calculator

Don’t guess at these costs. We created a free interactive tool to help you estimate your specific BOM, NRE, and operational expenses based on your target volume.

Launch The True Cost of Scaling Calculator

4. The Test Fixture: The Machine That Builds the Machine

How do you know the 5,000th unit coming off the line works? You don’t plug it into a laptop manually. You need an automated Functional Circuit Test (FCT) fixture—often a “bed of nails” rig that clamps down on the PCB to program firmware, test sensors, and verify power consumption.

Designing and building these fixtures is an engineering project in itself. You also pay for the cycle time: if your test takes 3 minutes and the factory charges €0.50 per minute, you just added €1.50 to every single device.

Estimated Cost: €15k – €40k (Hardware + Test Software)

5. Software at Scale: Security and Maintenance

Firmware for a prototype is about functionality. Firmware for production is about security and manageability.

- Secure Boot & Provisioning: Injecting unique cryptographic keys into every device on the assembly line so they can’t be cloned or hacked.

- OTA Infrastructure: You need a robust Over-The-Air update system to fix bugs post-launch. “Bricking” a device in the field is a disaster you can’t afford.

- Server Costs: The cloud back-end to support thousands of concurrent connections.

Estimated Cost: €30k – €100k (Dev + Infrastructure)

The Better Devices Approach: Scaling Smart

The gap between a $50 prototype and a market-ready product is not insurmountable—it just requires Systems Thinking and experienced planning.

At Better Devices, we specialize in navigating this transition. We don’t just build prototypes; we design for the Total Cost of Ownership. By integrating DFM, pre-certified modules, and automated testing strategies early in the design phase, we help you predict these costs and avoid the pitfalls that drain budgets.

Don’t let the cost of scaling catch you by surprise. Let’s map out your journey to mass production together.

Get a realistic production assessment from Better Devices today.