For technical leaders, the “testing phase” in embedded development often conjures images of lab benches, oscilloscopes, and logic analyzers. While crucial, traditional lab testing alone no longer suffices for the complexity of modern connected systems.

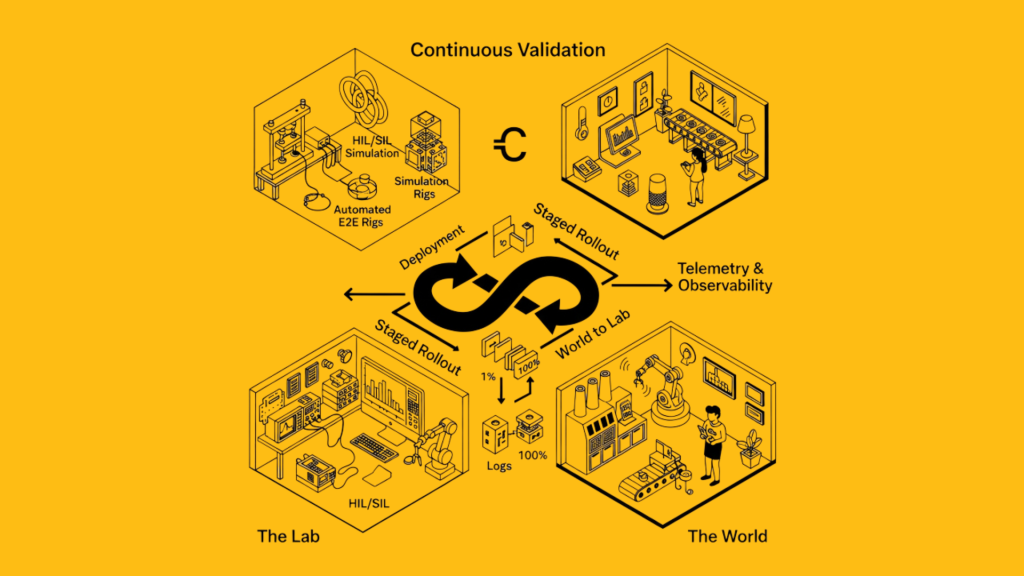

Today, successful product delivery demands continuous validation: an ongoing process that extends beyond controlled lab environments into real-world scenarios, leveraging data from deployment to inform development. This shift transforms testing from a late-stage gate to an integrated, iterative feedback loop, essential for quality, reliability, and market responsiveness.

The Blind Spots: Why Lab-Only Testing Fails

Traditional lab testing, while thorough for specific functions, often misses critical, real-world nuances:

- Environmental Variability: Lab conditions rarely mimic the fluctuating temperatures, humidity, RF interference, or power supply inconsistencies of the real world. A smart home device might work perfectly on a bench but fail under specific Wi-Fi interference in a crowded apartment.

- Edge Case Complexity: Devices interact with an infinite array of user behaviors, network conditions, and interoperating systems. Manually replicating every “what if” scenario in a lab is impractical.

- Scale & Fleet Dynamics: Issues unique to large-scale deployments—like thousands of devices reconnecting simultaneously after a network outage (the “thundering herd” problem)—are impossible to detect in a lab.

- Long-Term Degradation: Component drift, battery aging, and material fatigue occur over months or years, requiring continuous monitoring, not just a one-time test.

These blind spots necessitate a continuous validation strategy.

The 5 Pillars of Continuous Validation for Embedded Systems

Continuous validation integrates testing throughout the entire product lifecycle, from design to field deployment.

1. Hardware-in-the-Loop (HIL) & Software-in-the-Loop (SIL) Testing

- Purpose: To bridge the gap between pure simulation and full physical hardware.

- Method:

- SIL: Run embedded firmware on a PC, simulating the hardware environment to validate algorithms and logic (e.g., robotics control loops).

- HIL: Connect real hardware to a simulated environment to test the full embedded system (hardware + firmware) against realistic, dynamic inputs (e.g., simulating complex sensor inputs for an industrial controller).

- Benefit: Catch integration issues early, before full physical prototypes are ready, accelerating development cycles for wearables and robotics.

2. Automated End-to-End Test Rigs

- Purpose: To validate the complete system path from sensor to cloud and back, automatically.

- Method: Custom test setups that automatically exercise the device under various conditions, interacting with real external systems (e.g., cloud endpoints, mobile apps). These might involve robotic arms for simulating button presses or environmental chambers.

- Benefit: Ensure seamless data flow and functionality across all system components, vital for complex smart home ecosystems and industrial IoT deployments.

3. Real-World Scenario Emulation

- Purpose: To programmatically mimic adverse or typical operating environments in a controlled lab setting.

- Method:

- Network Emulation: Simulate flaky Wi-Fi, low cellular signal (LTE-M/NB-IoT), or high latency.

- Interference Testing: Introduce RF noise or electromagnetic interference (EMI) to stress wireless links.

- Power & Stress Testing: Automate long-duration power cycles and heavy load conditions to uncover stability issues.

- Benefit: Proactively identify vulnerabilities to common field failures (e.g., ensuring a wearable reliably reconnects after losing a phone signal).

4. Telemetry & Field Observability

- Purpose: To gather performance and failure data from deployed devices in the field.

- Method: Embed robust logging and reporting mechanisms (telemetry) in firmware. Collect key performance indicators (KPIs) such as device online rates, message latency, battery voltage slope, update success rates, and crash reports.

- Benefit: Identify emerging issues at scale, validate OTA update effectiveness, and inform future design iterations, crucial for managing large fleets of industrial or smart home devices.

5. Staged Rollouts & A/B Testing

- Purpose: To minimize risk during firmware updates and validate new features in a controlled, real-world manner.

- Method:

- Canary Deployments: Release new firmware to a small subset of devices first.

- Ring-Based Updates: Gradually roll out updates (e.g., 1%, then 10%, then 50%) across the fleet, monitoring KPIs at each stage.

- A/B Partitions: Implement firmware architectures that allow a safe rollback to a previous version if an update fails.

- Benefit: Prevent fleet-wide issues and ensure stability, critical for any product that receives frequent OTA updates.

Continuous Validation Strategies at a Glance

| Strategy | Description | Benefits | Example Industry Application |

| HIL/SIL Testing | Simulate hardware/environment for firmware/hardware validation | Early bug detection, parallel development, faster iterations | Robotics (control algorithms), Wearables (sensor processing) |

| Automated E2E Rigs | Programmatically test full device-to-cloud data paths | Validates system integrity, automates regression testing | Smart Home (app-device communication), Industrial IoT (data pipelines) |

| Real-World Emulation | Introduce environmental/network stressors in a controlled setting | Identifies robustness issues, prevents field failures | All (RF interference, power fluctuations, network drops) |

| Telemetry & Observability | Collect field data (KPIs, logs) for performance/issue monitoring | Proactive issue detection, data-driven improvements | All (fleet health, battery life, usage patterns) |

| Staged Rollouts | Gradual firmware/feature deployment with rollback capabilities | Mitigates risks of fleet-wide failures, ensures update stability | All (secure OTA updates for smart devices) |

From Bottleneck to Engine of Quality

For embedded systems, the era of testing solely in the lab is over. Continuous validation is an indispensable strategy for delivering resilient, high-quality products that meet real-world demands.

By embracing HIL/SIL, automated rigs, real-world emulation, telemetry, and staged rollouts, engineering teams can proactively identify and mitigate risks, shorten development cycles, and maintain product excellence long after deployment.

Connect with Better Devices to build embedded products that perform reliably, everywhere.